Why Is a Composite Label Film Needed? - To Overcome the Limitations of a Single Material

The label films made of a single material (such as BOPP, PE, PET) each have their own limitations:

BOPP: The label film is stiff and has good printability, but has poor flexibility and is not suitable for squeezable containers.

PE: The label film is soft and resistant to squeezing, but has poor stiffness and the print quality and texture are average.

All single plastic films: Their ability to block oxygen, water vapor, and odors is limited.

When the properties of these individual materials fail to meet the requirements, a composite film becomes necessary from China packaging manufacturers specializing in multi-layer solutions. Through its structural design, it combines the advantages of different materials.

For example: The outer layer uses BOPP to provide printing properties and hardness, while the inner layer uses PE to offer softness and heat-sealing properties. When these two layers are combined, a perfect label that is both aesthetically pleasing and sturdy, and suitable for HDPE extrusion bottles, can be obtained.

Main Application Fields of Composite Label Film

The composite label film, due to its outstanding comprehensive performance, is applied in fields where strict requirements are imposed on labels:

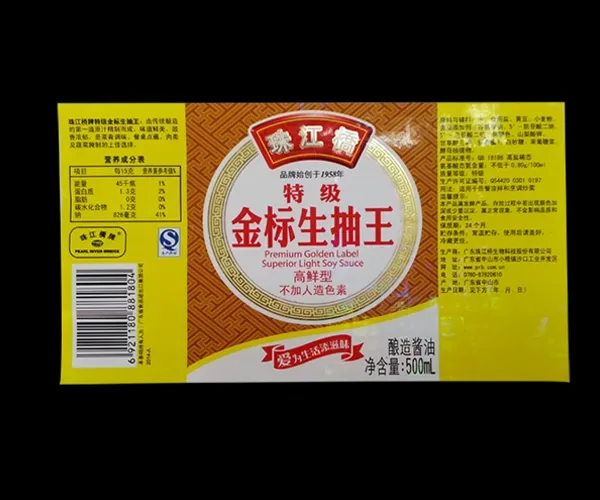

1. Contraction Labeling

This is the most classic application of the composite label film. The label is cylindrical and is wrapped around the container and then heated to contract, tightly covering the bottle.

Typical structures: OPS/PE, PET-G/PE, PVC/PE.

Advantages: The outer layer (OPS/PET-G) provides high contraction rate and exquisite printing; the inner layer (PE) provides a soft feel and tear resistance.

Applications: Full packaging for irregular-shaped bottles such as soy sauce bottles, cooking wine bottles, beverage bottles, health supplements bottles, cosmetics bottles, etc.

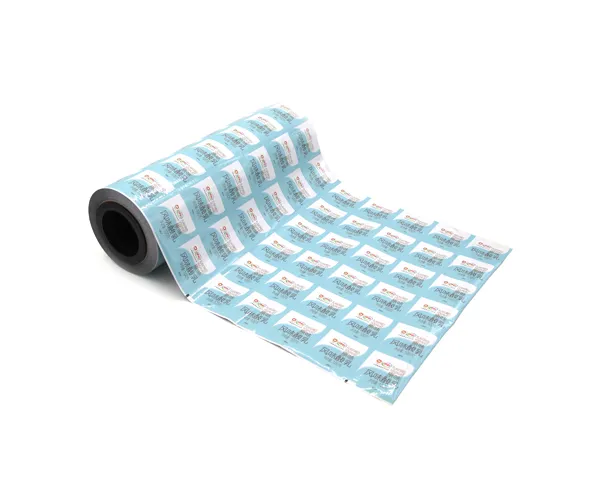

2. Wet wipe packaging cover film - This is a highly functional application.

Typical structure: PET/AL/PE.

Functions: PET (printing and strength), AL aluminum foil (high barrier, preventing water evaporation and bacterial invasion), PE (heat sealing layer, bonding with non-woven fabric packaging bags).

Applications: Packaging sealing for various wet wipes and makeup wipes.

3. High barrier content label - used to protect products that are sensitive to oxygen.

Typical structure: BOPET/EVOH/PE or BOPET/AL/PE.

Applications: High-end beer bottle labels, juice bottle labels, health supplement bottle labels, chemical labels.

4. Squeezable Container Labels - For packaging that requires pressing and squeezing

Typical Structure: BOPP/PE.

Applications: Labels for HDPE plastic bottles of shampoos, body washes, seasonings, etc.

5. Durable industrial and electronic product labels

Typical structures: PET/PA, PET/PET.

Advantages: Extremely high strength, high temperature resistance, chemical corrosion resistance.

Applications: Electrical nameplates, automotive part labels, outdoor equipment labels.

English

English  中文

中文