How to Choose a Right Vacuum Packaging Pouch?

The vacuum packaging pouch must have high barrier properties and excellent heat sealing strength to ensure the long-term maintenance of the vacuum state.

Common material structures:

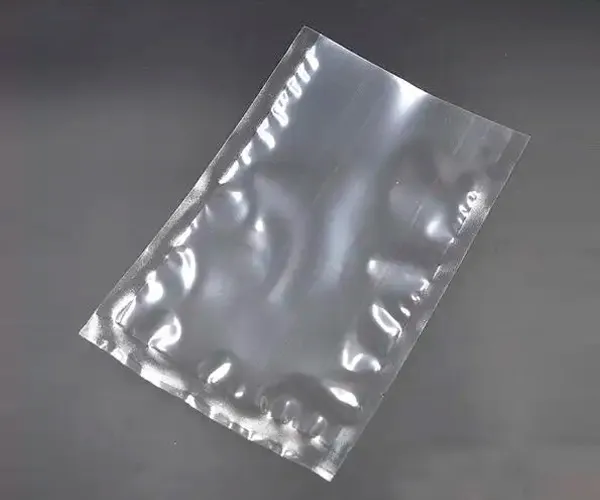

PA/PE (nylon/polyethylene): This is the most classic and common structure. Nylon (PA) offers excellent puncture resistance, impact resistance and toughness, preventing punctures by bones or hard objects; polyethylene (PE) as the inner layer provides excellent heat sealing performance and moisture resistance. This is the preferred choice for general-purpose vacuum packaging pouches.

PET/PE (polyester/polyethylene): PET provides higher strength and wear resistance, but its flexibility and puncture resistance are not as good as PA. It is often used for vacuum packaging of electronic products and non-food items.

PA/EVOH/PE (nylon/ethylene-vinyl alcohol copolymer/polyethylene): With the addition of EVOH, this ultra-high oxygen barrier layer provides ultimate oxygen barrier performance. It is used for highly sensitive products to oxidation, such as premium meats, seafood, coffee beans and certain pharmaceutical products.

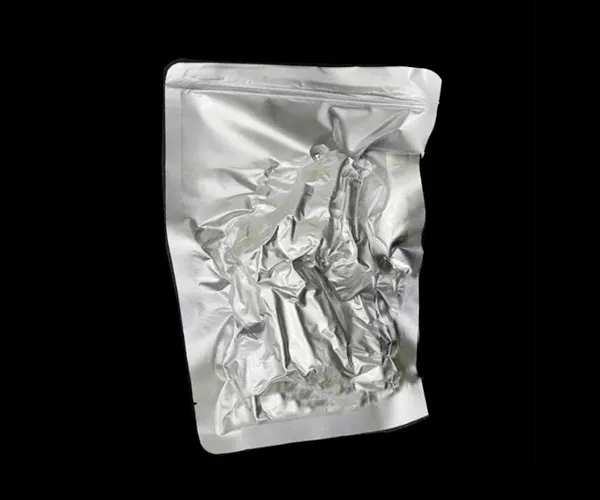

Aluminum foil composite structure: Such as PET/AL/CPP, it provides the highest level of all-round barrier (oxygen barrier, moisture barrier, light protection), and is often used for vacuum products that require long-term storage or high-temperature sterilization (such as soft cans).

What's the Application of Vacuum Packaging Pouches?

The vacuum pouches wholesale have extremely wide applications, mainly revolving around "preservation and preservation from spoilage" and "physical protection":

Food Industry (the main field):

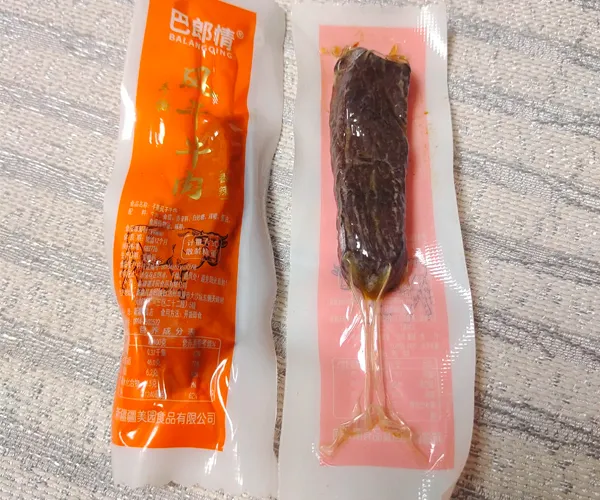

Fresh meat and poultry: The vacuum packaging pouches extend shelf life and maintain meat color.

Cheese and dairy products: The vacuum packaging pouches prevent mold growth and flavor loss.

Cooked and processed meats: sausages, ham, bacon.

Seafood and fish: The vacuum packaging pouches maintain freshness.

Nuts and dried goods: The vacuum packaging pouches prevent oil oxidation and moisture absorption.

Electronics and precision instruments:

Moisture-proof, oxidation-proof, dust-proof, used for circuit boards, precision parts, etc.

Medicine and healthcare:

Home and collection:

Advantages and Challenges of Vacuum Packaging Pouches

Advantages:

1. Significantly extend shelf life: Under refrigeration or freezing conditions, the vacuum pouches wholesale can extend the shelf life of food by several times.

2. Maintain product quality: The vacuum pouches wholesale can effectively preserve the color, aroma, taste and nutritional value of the product.

3. Prevent freezer burn: During the freezing process, the vacuum environment can prevent the evaporation of water on the surface of the food, which leads to drying and deterioration of the quality.

4. Save space: The compression feature makes the package volume smaller after compression.

Challenge:

1. Unable to inhibit anaerobic bacteria: Although the vacuum environment inhibits aerobic bacteria, it may provide conditions for anaerobic bacteria such as botulinum. Therefore, vacuum-packed foods (especially those with low acidity) usually require refrigeration, freezing or sterilization treatment in conjunction.

2. Equipment dependence: The use of vacuum packaging machines increases the initial cost and operational steps.

3. Packaging cost: The cost of the vacuum packaging pouches themselves and consumables (such as vacuum machines) is higher than that of ordinary plastic bags.

4. Product shape limitation: For products with sharp edges, there is a risk of puncturing the vacuum packaging pouch.

English

English  中文

中文