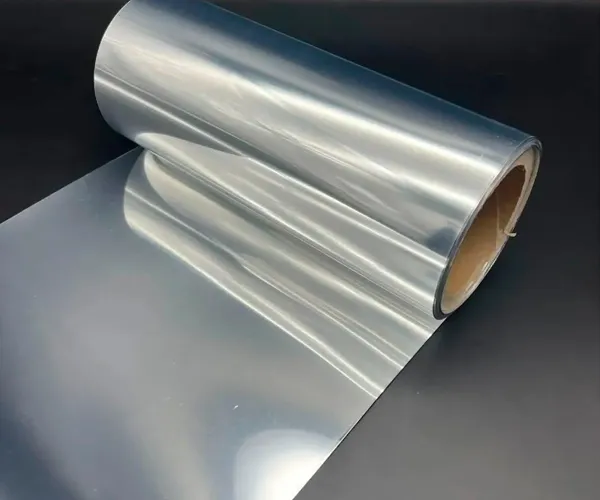

Extremely high water vapor barrier: far exceeding that of ordinary PE films, it can effectively prevent the contents from getting damp or drying, significantly extending the shelf life.

Excellent oxygen barrier: filling the gap of ordinary PE films in oxygen barrier, it can effectively prevent the contents from oxidizing and deteriorating (such as spoilage of snacks, loss of flavor).

Complete light-blocking and high UV resistance: the aluminum layer can 100% block light, which is crucial for light-sensitive contents (such as oils, medicines).

Solutions

- Recyclable Flexible Packaging

- Retort Pouch Flexible Packaging

- Dry Food & Snack Flexible Packaging

- Home & Personal Care Flexible Packaging

- Sauce & Condiment Flexible Packaging

- Dairy Products Flexible Packaging

- Frozen Food Flexible Packaging

- Pet Food Flexible Packaging

- Beverage Flexible Packaging

- Pharmaceutical Flexible Packaging

- Custom Flexible Packaging

What are you looking for?

English

English  中文

中文