Extrusion lamination is a lamination process in which polyethylene and other thermo-plastic materials are molten in an extruder, and then extruded into a flat die, which becomes a flat film that flows out, and is immediately laminated with another film or two films by cooling rollers and laminating rollers. Extrusion lamination plays a very important role in the lamination process of flexible plastics. Compared with other lamination processes, extrusion lamination has many advantages: lower cost, cleaner production environment, higher production efficiency, high flatness of the laminated film, and very low or no solvent residue.

Extrusion lamination is widely used in food packaging industry, especially in pharmaceutical packaging industry. Because extrusion lamination has very low or even no residual solvents compared with dry lamination, with the heat seal layer produced under GMP production environment, the hygiene performance will be better. These advantages make extrusion lamination an important lamination process for pharmaceutical packaging with laminated films, so extrusion lamination holds an important position in pharmaceutical packaging.

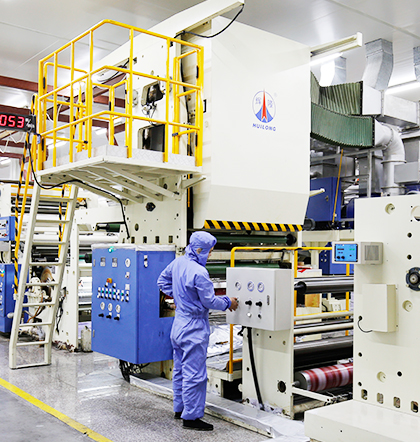

Novel Packaging is equipped with many world-class brand laminating machines, so as to provide better guarantee for the products' quality. In these decades, through high quality products, Novel packaging has helped our clients to win market share for their extrusion lamination process.