Why do polymer films experience color peeling or sticking problems during printing?

Color peeling: It may be due to insufficient surface tension of the film. After production, the film needs to undergo "corona treatment" to increase its surface energy, allowing the ink to adhere firmly. The treatment effect will diminish over time.

Printing adhesion: It may be caused by the ink not being completely dry, excessive winding tension, or too high temperature, resulting in the ink or film layers sticking together.

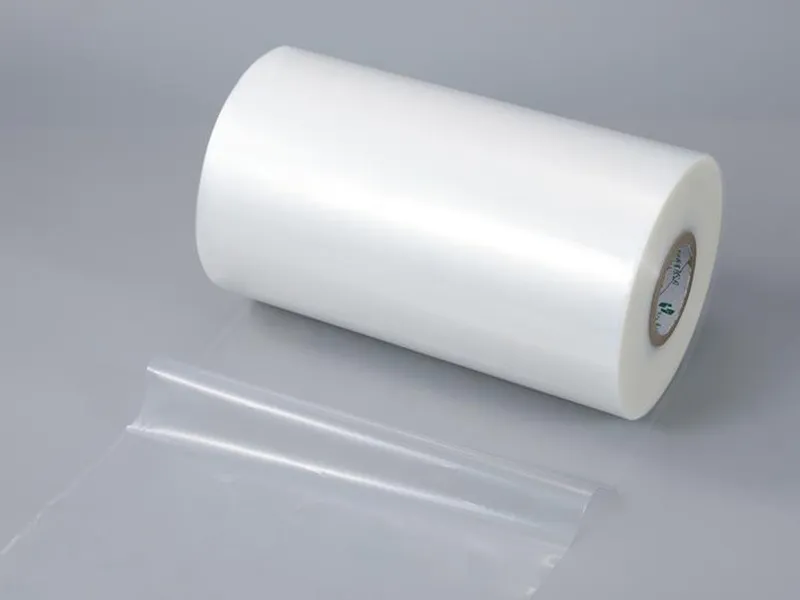

How to store plastic film rolls?

Vertical storage: Roll films should be placed vertically to avoid deformation caused by horizontal placement.

Light-proof and moisture-proof: Store in a cool and dry indoor environment, away from direct sunlight. Some materials (such as nylon) are prone to moisture absorption.

Constant temperature: Avoid storing at excessively high or low temperatures.

First in, first out: Arrange inventory reasonably to prevent the performance of films from deteriorating over time.

How to determine the quality of a film's barrier properties?

Barrier properties are the core ability of a film to protect the contents. They are mainly measured by two professional indicators:

Water vapor permeability: The lower the value, the better the moisture-proof performance.

Oxygen permeability: The lower the value, the better the anti-oxidation performance and the longer the shelf life.

For example, ordinary PE bags have poor oxygen barrier properties, while composite films with aluminum foil, EVOH or PVDC coatings belong to high-barrier materials.

Why do plastic films tend to have problems during printing?

Common issues and causes:

Poor adhesion: The surface tension of the film is insufficient (requires corona treatment).

Misalignment during printing: The film expands or contracts due to heat or tension during the printing process.

Odor: Residual ink or solvent, which may be related to the quality of the ink or incomplete drying.

What key parameters need to be provided when ordering plastic film?

Material and structure: For example, all-PE bags, or PET//PE composite film.

Thickness and width: Thickness (in μm or filaments, 1 filament = 10 μm) and the width of the roll material.

Color and transparency: Transparent, white, black or other custom colors.

Surface treatment: Whether electrostatic treatment is required and the required durometer value.

Special properties: Such as anti-static, high barrier, high temperature resistance, recyclable, etc.

What is the ''heat sealing property'' of a polymer film?

It refers to the film's ability to fuse and bond with other films when heated and pressurized. The quality of the heat sealing performance directly affects the sealing performance of packaging and production efficiency. PE and CPP are commonly used heat sealing materials.

What is ''aluminum-coated film''?

It is a film formed by vacuum evaporation of a very thin layer of aluminum molecules on a plastic film (such as PET or CPP). It combines the flexibility of plastic and the metallic luster and good barrier properties of aluminum, with a lower cost than pure aluminum foil. It is widely used in packaging for snacks, coffee, etc.

English

English  中文

中文