Pharmaceutical Packaging film

We offer popular packaging options for Pharmaceutical packaging

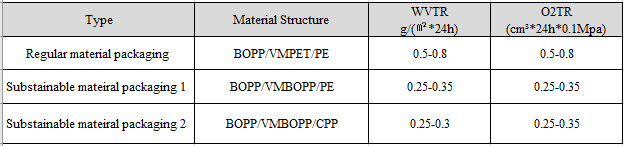

According to Pharmacopoeia 2020 edition, the difference between the measured value and the mean value of each test product shall not exceed 10% of the mean value, except for the high barrier performance test product [O2TR result less than or equal to 0.5cm3/(m2.24h·0.1MPa)]. The measured value of each test product with high barrier performance shall not be greater than 0.5cm3/(m2.24h·0.1MPa).

The difference between the measured value and the mean value of each test product shall not exceed +10% of the mean value, except for the high barrier performance test product [WVTR result less than or equal to 0.5g/(m224h)]. The value of high barrier performance test shall not be measured each time > 0.5g/(m2:24h).

Oxygen, moisture, odor, puncture, and often UV rays are the most concern points of pharmaceutical packaging. Especially the Oxygen and moisture, this ensures a longer shelf life of the packaging.

We offer packaging film for pharmaceutical tablets packaging, granules packaging and capsules packaging, etc. Material structure can be PET/VMPET/PE, PET/AL/PE, PET/ VMCPP, BOPP/PE and other material structure.

The O2TR and WVTR deviations of VMPET composite film are difficult to meet the requirements, which is the major point we are struggling to overcome with.

Guangzhou Novel adopted the new technology of Alu Bond and successfully improved barrier property of the VMPET. Both O2TR and WVTR of the composite films are < 0.5, which meets the high barrier requirements of the new pharmacopoeia.

Moreover, we are committed to developing Mono environmentally friendly materials. Under the requirement of green sustainable packaging, the development of Mono environmentally friendly material is one of direction we are struggling for.

Application:

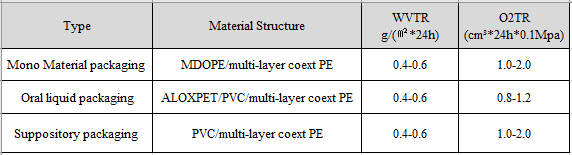

Transparent high barrier composite packaging films are also the direction we are promoting at present. It has following characteristic:

1. High water vapor, oxygen barrier

2. Long shelf life of packaged products

3. Reduce weight loss of water content

4. Reduce moisture absorption of dry contents.

Application: